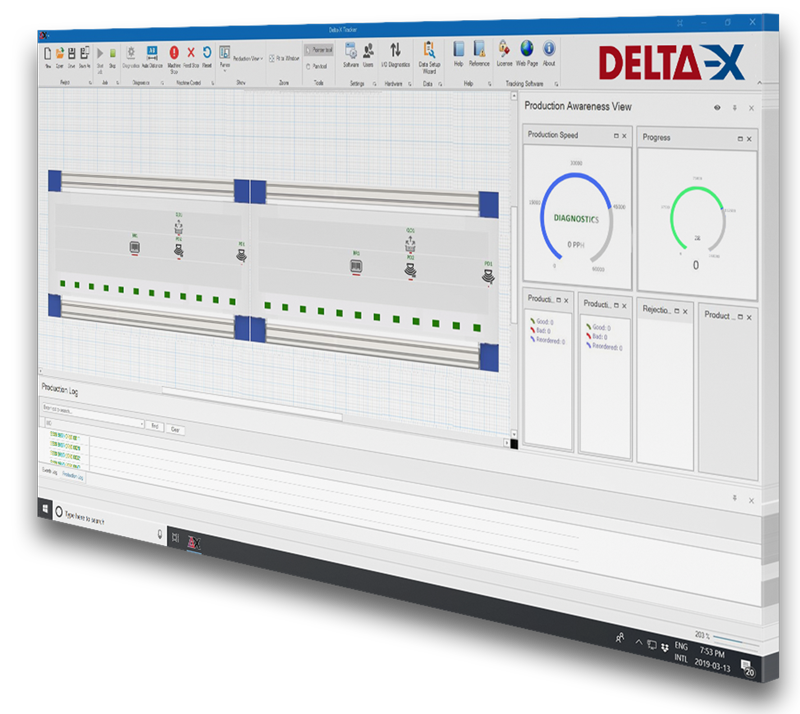

Real-time Product Track and Trace

Delta-X™ Tracker

The next-generation Inline solution for variable data embedding, tracking, validating and reporting, with unprecedented tracking speed and capacity.

Delta-X Tracker is the most flexible solution built to track and trace products and prove the integrity of the production. Delta-X Tracker offers real-time data reading, validating, reconciling and reporting with world-leading speed and accuracy. Real-time control, interaction and interface with any data structure, such as barcode reading and grading, visual and OCR inspection, DOD and label printing, magstripe/chip encoding and verification, batching and diverting, and multi-level aggregation on the production line.

The Delta-X™ Tracker solution is a software and hardware solution to provide the most accurate track-and-trace functionality in the industry. We support tack and trace throughput up to 60,000 PPH and tracking speed up to 700 ft./min (200 m/min).

An Industrial-grade computer with modular and compact I/O design, supporting up to 16 tracking zones, 64 Channel for Sensors and Trigger Outputs, 8 Industrial Printers (Smart-Jet DOD Inkjet Printer/ Zebra Label Printer), and 16 peripheral devices (Inspection Camera, Barcode Readers, Magstripe Reader/Encoder).

Full SpecificationsRe-produce rejected products on-the-fly (Quick reproduction) or at the end of production (Post-job reproduction).

Delta-X Tracker offers real-time data reading, validating, reconciling and reporting with world-leading speed and accuracy.

Access from anywhere on the globe. Simple, intuitive UI with tutorials to engage and support users throughout the journey.

Role-based access control (RBAC) allows administrator to specify access privileges at various levels. Administrator can specify who has granular control over operations to create and modify different types of data and records.

Modern windows-themed GUI designed for quick on-boarding and user engagement. Documentations and Tutorials supports operators to be productive on day one.

Data of every finished product is logged and kept safe by Delta-X, allowing you to quickly resume production following outages to minimize impact and losses.

Search, filter, export and print reports from up to 8 customized report generation points. Create customizable and flexible reports from gathered post-production data, or live production report in any location of machine.

Seamlessly integrate with ERP, MES, EPCIS systems and major RDBMS such as SQL, MySQL, Postgres SQL and Oracle to eliminate duplication risk.