All-in-one Production Site Management Solution

Delta-X™ SiteCentral

Plant-based Line Management hub to assign jobs, monitor production, collect data and maintain equipment.

Improve job management efficiency with full visibility across the print production floor. Monitor operations, production status, bottlenecks and failure points on production of connected machines.

Designed to collect real-time data from multiple location and machines, Delta-X™ SiteCentral provides a graphical overview onsite asset, production performance and maintenance.

Seamless transaction of operation and production data is made possible using Pack-Smart I/O Controller, or other system and PLC’s by using OPC DA and Modbus TCP/RTU.

Operation manager can schedule and assign jobs to machines from centralized location and monitor the production status on assigned jobs. Operators can see notification for new jobs or updates and are able to run a job or return a job to central job repository. All of data is encrypted to meet or exceed PCI standards.

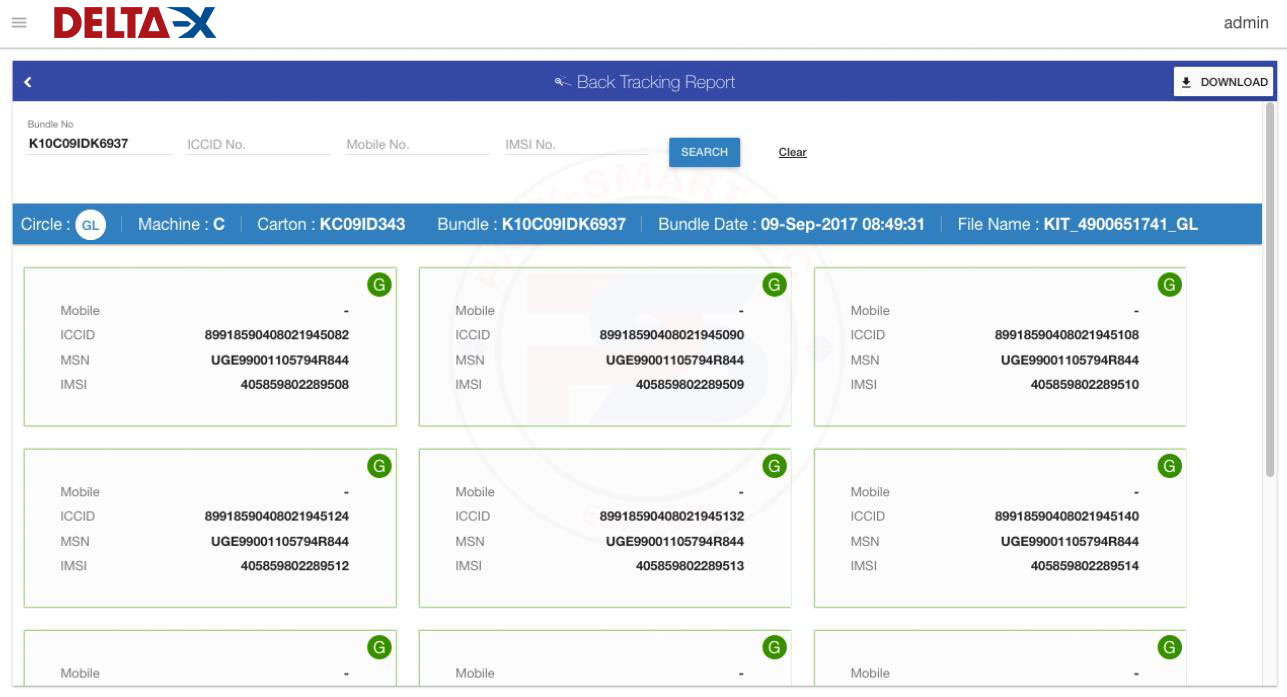

Tracking of production history is available for user to search in the production reports and review the history of the product produced. Report is based on individual products produced, available at any time or machine.

Designed to improve the production by providing comprehensive maintenance service planning, labour scheduling and spare part inventory control. Anticipates work orders such as manual work orders, routine and preventative maintenance, and schedule resources on maintenance operations.

Seamlessly integrate with ERP, MES, EPCIS systems and major RDBMS such as SQL, MySQL, Postgres SQL and Oracle to eliminate duplication risk.

Build customer confidence and one-up your competitors with uncompromised, bank-level security. All your data is stored in a dedicated Crypt, protected using AES-256 encryption, and communicated via SSL using 2048-bit certificates.

Role-based access control (RBAC) allows administrator to specify access privileges at various levels. Administrator can specify who has granular control over operations to create and modify different types of data and records.

Spare part inventory control helps maintenance team to review parts, technical information, supplier information and availability, assign spare parts to work order, and track parts replacement history.

Enables maintenance supervisor to assign and schedule available labours to work orders. Maintenance team receives notification when a work order is created or updated.

Monitor operations, production status, bottlenecks and failure points on production of connected machines. Customizable reports available to users down to individual machine levels.

Designed to prevent unexpected equipment failure by computing the remaining life span of equipment based on the operation, counters, trigger point, limit and more. Maintenance order or notifications can be scheduled to launch when a component reach its end-of-life.

Depending on your needs, SiteCentral can be installed locally, on a private cloud, or hosted on our server and accessed through a web browser.